- Via Libero Grassi snc – Loc. Rabatta - 50032 Borgo San Lorenzo (FI)

- info@gbinoxsrl.it

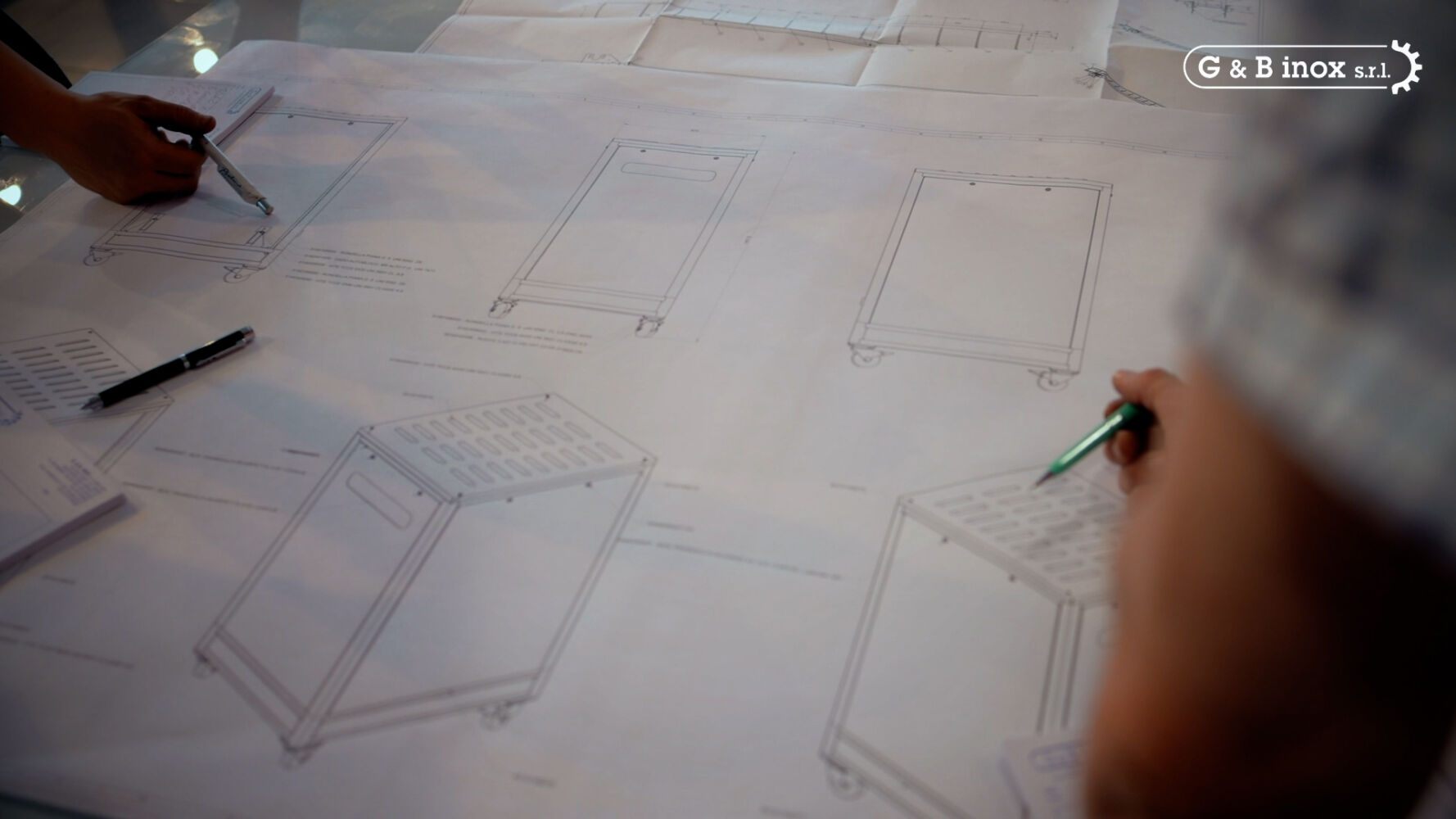

Established in 2007, G&B Inox Ltd. is a Tuscan company from the Industry 4.0 sector that operates in the mechanical engineering field with third-party productions. It specializes in metal constructions (stainless steel, iron, aluminum), laser cutting, lasertube…

It stands out for its product quality, offering custom processing and professionalism dedicated to customer service. Over time, the company has grown and now has 75 employees (including production and office staff).

There has been a consistent commitment to technological innovation, coupled with increasing attention to the quality of the finished product. The company also emphasizes the professionalism of its services and punctuality in deliveries.

G&B Inox is located in Borgo San Lorenzo (Florence) and is organized into three warehouses, covering a total area of 3,000 m²:

A new warehouse is under construction, which will be owned by the company; it will be exclusively used as an assembly area.

The company has various vehicles ensuring maximum punctuality in deliveries:

The main sectors in which the Florentine mechanical engineering company operates are processing for the packaging, pharmaceutical, food, and furnishing industries.

G&B Inox has a growing technological park to offer every customization possibility to the customer.

With the introduction of highly productive technology such as the new 10KW Fiber Laser connected to a multi-pallet automatic loading/unloading tower, expansion of the machine tool department with a second CNC lathe, a second 5-axis work center, the electric and mechanical assembly service using innovative 3D CAD software, the customer is assured of a quality finished product.

The company is structured to meet any mechanical carpentry project, offering a wide range of products and processes for each specific request, with the ability to also cut brass and copper in a work area of 2000x4000mm.

If you want to rely on a specialized mechanical engineering company for metal constructions (stainless steel, iron, aluminum), contact G&B Inox for a quote or for information.

G & B INOX SRL P.IVA 05778490481 | URI FIRENZE | N.REA 574429 | CAP.SOC. 10.000

Scrivici su WhatsApp!